The role of U/V structure in spark plugs

Release time:2025-10-22

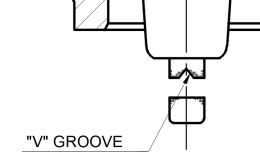

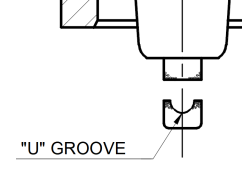

The design of the center electrode with a V-groove or the side electrode with a U-groove wire is fundamentally due to the creation of a sharp corner at the ignition end of the electrode. Under high voltage, the charge gathers at the tip of the ignition end, which is conducive to the occurrence of breakdown ignition.

The design of the center electrode with a V-groove or the side electrode with a U-groove wire is fundamentally due to the creation of a sharp corner at the ignition end of the electrode. Under high voltage, the charge gathers at the tip of the ignition end, which is conducive to the occurrence of breakdown ignition.

The figure shows an example of the electron density at the electrode tip under voltage in a center electrode V-groove.

The use of a U/V structure can reduce the sparkover voltage and ease the difficulty of sparkover, significantly reducing misfire rates. Therefore, it is often used in spark plug designs, such as NGK's V-line series, which features a center electrode V-groove. DENSO products, on the other hand, mostly use a U-shaped side electrode.

Similarly, in spark plugs, the side electrode covers three-quarters of the center electrode, also utilizing more of the sharp corners facing the ignition electrode.

The required sparkover voltage is reduced, which helps reduce the risk of leakage. When insulation in ignition systems such as high-voltage wires deteriorates, ground leakage can occur if the ignition voltage exceeds a certain threshold—a threshold voltage lower than the sparkover voltage. This also improves performance when the battery level is relatively low.

Related News

Contact Information

Add: Building A3-306 Lugu Enterprise Square, No.27 Wenxuan Road, Changsha, Hunan Province ,China